![]()

Where does all the time go?! Well, there ahve been several years of very enjoyable hassle-free motoring, and a whole raft of updates.

1 - After a few years on the road there was a fair amount of creaking, rattling and general odd noises from the Mojo, especially around the rear end so a stripdown/rebuild was in order. The first thing that was apparent was that the metalastic bushes had all moved so that there was a lot of metal-on-metal contact.

After looking online for some replacements it became clear that these particular bushes have the rubber bonded to the inner sleeve, but not the outer so they will always have a tendency to creep. On further inspection the bushes themselves weren't damaged and could be pressed back into position quite easily. To prevent the problem happening again I fitted some thrust washers. These were cur from a plastic oil drum using a holesaw and do the job very well.

2 - While the suspension was apart, I changed the top rear balljoints as one of them had a split in the rubber. For reference, these are MK2 Fiesta balljoints, FirstLine part FBJ5108.

3 - Since the car was in bits, it made sense(!) to completely replace the interior and reskin all of the aluminium panels. This time I used liquid contact adhesive rather than the spray on type I used last time.

4 - And if the interior is out, then why not go for some new seats too? I'd been thinking about fitting JK Composites seats for some time now so it was a sensible time to go for it and get these. The drivers seat is fitted using OMPHC665 seat runners from Demon Tweeks, and the passenger side is fitted rigidly using two strips of wood as spacers.

5 - I had originally fitted a heater valve, but never actually got round to wiring it in. Since the coolant was drained then it seemed to be a good time to remove it.

6 - Other items included fitting a new rocker cover gasket to stop a small oil leak, an oil change, a coolant flush, and a new numberplate.

After all of those mods, and a new MOT, I spent a couple of months just enjoying driving, including a very enjoyable trip up to Stoneleigh.

There were, however, a few things that were still causing concern.

1 - The tyres I had fitted were the originals from the build and were too hard and not really suited to the car. After much investigation, I took the option to fit some Toyo R1R's which not only look great, but also seem to stick to the road like s**t to a blanket. :)

2 - The tracking was way out so a trip to AB Performance for a full set up was arranged. Before going though, it seemed sensible to do something about the rear toe links that offered limited adjustment possibilites. A quick night of research followed by an order to McGill Motorsports resulted in this:

After a very enjoyable morning with Andy Bates, we had gone over all of the major measuements and came up with some good positives and a list of things to concentrate on next. The measurements after all was completed were as follows:

Tyre pressures:

All set to 18psi (the R1R’s have quite soft sidewalls.)

Toes:

Front: +0.5mm| +0.5mm (1mm toe out; this was 4mm toe out!)

--------------------------

Rear: 0.0mm | 0.0mm

Cambers:

Front: -1.5° | -1.5°

--------------------------

Rear: -1.5° | -1.4°

Weights:

Total including me & full tank: 674.5kg

Corners (kg)

Front: 120.5 | 140.5

--------------------------

Rear: 202 | 212

Corners (%)

Front: 18% | 21%

--------------------------

Rear: 30% | 31%

Ride heights:

Front: 110mm | 110mm

--------------------------

Rear: 125mm | 135mm

We tried raising the right rear to load up the front left a bit more but didn’t get any real gain on what was shown above which led us to believe that the standard 300lb/275lb springs area bit too stiff for the chassis, and the chassis is deflecting as much as the suspension. Time for some much softer springs and maybe an anti-roll bar or two? Certainly when compared to one of the AB race cars, the current suspension is rather wooden and a bit more compliance would really help in order to find any further benefits.

Other things that we saw were that I would benefit from doing some engine mount mods to raise the engine and straighten the driveshafts a little, and this would require a new exhaust manifold to make space in the engine bay. Both of these would liberate a few more horses (as well as a few £££ no doubt).

It also became clear during some of the test runs that my stock M16 callipers are a bit of a limiting factor and although they’re perfectly fine for my normal road driving, they fade alarming quickly when pushed, even with Mintex 1144 pads.

Regarding other measurements; bump steer was negligible both front and back, and my unsprung weight is a fairly hefty 30-35kg per corner. Once I’ve sorted out the engine mounts I should be able to drop the ride height by around 20mm which will give me back some droop in the suspension too. I’d always known that it tended to bottom out over potholes, and therefore tried to avoid them, but it would be good to sort this out properly.

Which brings nicely onto:

3 - The driveshaft angles were a bit too steep and there were some odd noises coming from the CV joints when the suspension was in compression.

The Puma engine was originally fitted lower than the 1.25 engine to make room for the larger inlets and different engine mount arrangement. This was now becoming a problem and a better solution needed to be found. A decision was made to try and fit an inlet menifold from a 1600 Zetec SE which is plastic and much smaller than the 1.7 aluminium one. It's an almost perfect match and fits the ports very well, so while there may be a very slight drop in performace, it is going to be more than compensated for by the reduction in losses in the CV joints.

The new inlet manifold arrived (£20 from eBay) and it was noticed that the vacuum sensor was different from the Puma one and in a position where it clashed with the alternator. That was promptly removed and an aluminium blank plate fitted in place. A new hole with an appropriate 3/8NPT thread was drilled and the Puma sensor connected.

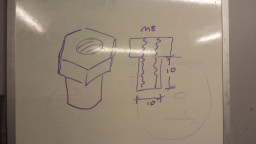

The plastic manifold flange is much thicker than the Puma aluminium one, so some longer bolts were needed to fit it to the block. There are 3 fixings at the bottom that go into the blcok and 5 fixings into the cylinder head; 3 bolts and 2 studs. Unfirtuantely the studs were also too short but I couldn't find an easy/safe way to remove them from the block so I had some sleeve nuts made (M12 bolt turned down and tapped with an M8 thread).

All the fixings were tightened to 18Nm and this part of the job is done.

So next; with the engine mounts removed, the optimal position was found.

The rear shocks are 13" open, but I have the 1" top hat extensions fitted so they are now 14". I wanted to allow for more rebound so I made up some wooden spacers to replace the shocks that will hold the car at 13" shock extension. This is to allow 1" for droop, and 2" for compression movement.

The existing engine mounts needed some significant modifications so a day with the grinder and welder produced these:

The gearbox mount has gone back to standard, and the belt end mount has had to be completely remade to allow for the VVT mechanism on the 1.7 engine.

The revised engine position also meant that I could refit the Fiesta 1.25 v-belt tensioner pulley and still have enough clearance between the pulley and the chassis. The belf fitted is now a QBR1175.

Next job - turning all of this into an exhaust...

![]()